Water systems, including pipelines, storage tanks, and industrial equipment, are highly susceptible to corrosion, which can lead to costly repairs, operational downtime, and safety hazards. One of the most effective ways to detect early signs of corrosion is by monitoring the pH of water. Slight shifts in acidity or alkalinity can accelerate metal degradation, making timely detection essential for maintenance and prevention strategies.

Corrosion often begins subtly, with small changes in water chemistry that precede visible damage. Monitoring these changes allows facility managers to intervene before extensive deterioration occurs. By tracking pH levels consistently, operators can identify patterns that indicate the onset of corrosion, such as acidic conditions that promote rust formation or alkalinity shifts that affect protective coatings.

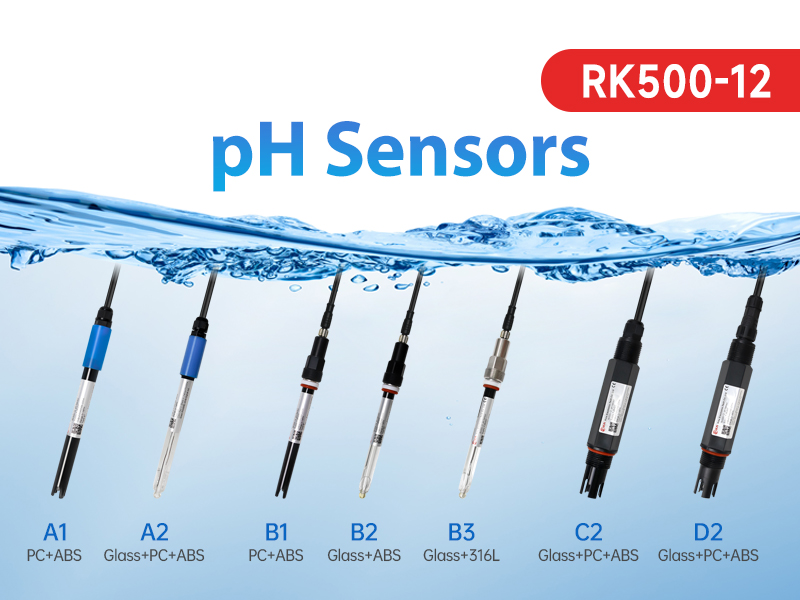

A pH Sensor for Water is an invaluable tool for detecting early corrosion signals. These sensors provide accurate, real-time measurements of water acidity and alkalinity, enabling engineers to take preventive action before structural damage occurs. By integrating pH sensors into water monitoring systems, facilities can maintain system integrity, extend equipment lifespan, and optimize maintenance schedules.

Understanding the Relationship Between pH and Corrosion

The pH of water directly affects the electrochemical processes that cause corrosion. Low pH levels (acidic water) accelerate the dissolution of metals such as steel and iron, leading to rust and structural weakening. Conversely, extremely high pH levels can affect protective oxide layers, also contributing to corrosion. Maintaining water within an optimal pH range is essential to protect pipelines, tanks, and machinery.

By continuously monitoring pH, operators can detect deviations from safe ranges early, allowing for adjustments in chemical treatment or water conditioning processes. This proactive approach minimizes damage and reduces the likelihood of emergency repairs.

Benefits of Real-Time Monitoring

Real-time monitoring with pH sensors provides immediate insights into water quality, enabling quick response to potential corrosion risks. Traditional sampling methods can miss short-term fluctuations that may accelerate metal degradation. Continuous pH measurement ensures that even transient changes are captured, providing a more complete picture of water chemistry.

This capability is particularly important in industrial systems or municipal water networks, where water chemistry can vary due to temperature changes, flow patterns, or chemical dosing. Early detection of pH anomalies allows operators to implement corrective measures, such as adjusting inhibitors, modifying chemical dosing, or flushing affected sections.

Integration with Corrosion Control Strategies

pH sensors can be integrated into broader corrosion control programs. Combined with other monitoring tools, such as conductivity sensors, dissolved oxygen meters, and corrosion rate probes, they provide a comprehensive approach to system protection. Data from these sensors can be analyzed to optimize treatment strategies, ensuring that inhibitors, coatings, and other protective measures function effectively.

Using pH sensors as part of an integrated system enhances predictive maintenance, allowing engineers to plan interventions before significant damage occurs. This approach reduces operational costs and extends the service life of critical infrastructure.

Enhancing Safety and Compliance

Corrosion not only compromises system performance but also poses safety risks, including leaks, contamination, and structural failure. Monitoring pH levels helps ensure that water systems operate within safe chemical ranges, preventing hazardous conditions. In regulated industries, maintaining proper water chemistry is also necessary for compliance with safety and environmental standards.

High-quality pH sensors provide reliable data for documentation and reporting, supporting regulatory compliance and risk management initiatives. Continuous monitoring reduces uncertainty, helping organizations demonstrate proactive maintenance practices.

Long-Term Equipment Protection

Consistent pH monitoring supports long-term equipment protection by providing actionable insights into water chemistry trends. Facilities can track changes over time, identify recurring issues, and refine corrosion prevention strategies. By detecting early warning signs, pH sensors reduce the frequency and severity of maintenance interventions, saving time, labor, and costs.

Practical Applications

pH sensors are used in various industries to prevent corrosion in water systems, including power generation, chemical processing, food and beverage production, and municipal water distribution. They are also used in laboratories and research facilities to study water-metal interactions, optimize treatment processes, and test corrosion inhibitors.

Conclusion

A pH Sensor for Water is a critical tool for detecting early signs of corrosion in pipelines, tanks, and industrial systems. By providing accurate, continuous pH measurements, these sensors allow operators to identify potential risks, optimize chemical treatments, and implement preventive strategies. Integrating pH monitoring into water management programs enhances system reliability, extends equipment life, and reduces operational costs, ensuring safe and efficient water system operation.